Horizontal Rod Railing and Stair Systems

Simple, Elegant Metal Railings and Stairs

Click on images to enlarge.

Click on images to enlarge.

Click on images to enlarge.

Stair Railing Systems

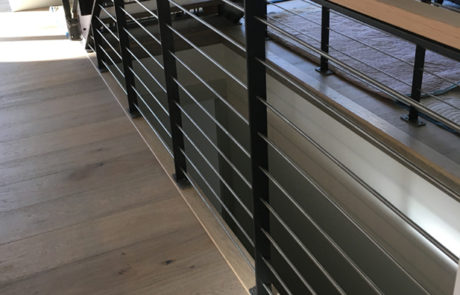

Proportionally designed floor- and fascia-mounted posts and .3125 in. horizontal stainless steel rods create a well-balanced railing system. Rods are passed through steel posts and held with a set screw. This results in a clean modern look as well as an extremely safe railing. For interiors posts and top rails are clear coated with a satin (20% sheen) lacquer finish. For exterior work we use a satin black oil-based paint with a sprayed-on finish. The stainless-steel rods (for interior and exterior) are brushed to a satin sheen. Posts are a maximum of 32 in. apart. Railing heights are to code at either 36 or 42 in. high. Posts and top rail are .375 in. thick by 1.75 in. wide. Rods are spaced to code at approximately 3.75 in. This design gives you clean end posts with a simple dot pattern.

Optional stainless-steal stabilizing brackets available for longer railing lengths.

We also offer customized systems and elements:

- Inside and outside corners

- Curved railings

- Custom mounting brackets for side mounted systems

- Round .875 in. posts and top rail system

Metal Stair Systems with Wood Stair Treads

The stair system is based on a c-channel industrial look with mechanical fasteners, easily secured to the header and floor with lag bolts. The contrast of the mill-finish metal profiles interlaced with the stainless rods creates a pleasing sleek esthetic. The addition of the wood treads softens the look and adds warmth for both residential and commercial appeal.

- Treads are 1.5 in. thick and 13 in. deep starting at minimum width of 36 in.

- Wood is specified by client

- Additional tread materials available upon request

Attaining length measurement for rail system:

- Determine smallest distance between walls where the railing will fit. Do this by using a level to determine if the walls are plumb and flat.

- Mark on the floor, the point on each wall where the level reads plumb. This is the smallest measurement.

- Measure between these two points. Subtract 1/16″ for clearance. This is the overall length of the rail system.

For detailed information and specifications click here.

Tell Us About Your Project

If you’d like to set up a consultation or request a bid please tell us something about your project. (all fields are required)